-

Markets

We were born and raised in one of the most important areas in Italy for everything related to the processing of tape and wire, a district of excellence that responds to the demand for products dedicated to the entire small parts sector. In many years of work we have been able to successfully intercept the needs of very different sectors, including automotive.

-

Quality system

The Quality Management System is a well-defined and integrated procedure in our company, as the first ISO 9001 accreditation dates to 2004. Melesi G has always strongly believed in this indispensable tool to better manage all production phases. Following the structural expansion, which took place during 2020, Melesi G has reserved an important space for the Quality Control office; within which, we can find contact, fatigue, hardness and optical control machines, interlaced to the company 4.0 network and all integrated with the MES Management System. Manufacturing Execution System, more commonly known as Mes, for Melesi G, combines all the work phases, from the entry of the Customer Order, Planning, Processing, Treatments, Dimensional and Quality Controls, up to Packaging and Shipping. All this guarantees real-time monitoring of all the working phases of the requested product.

-

Production

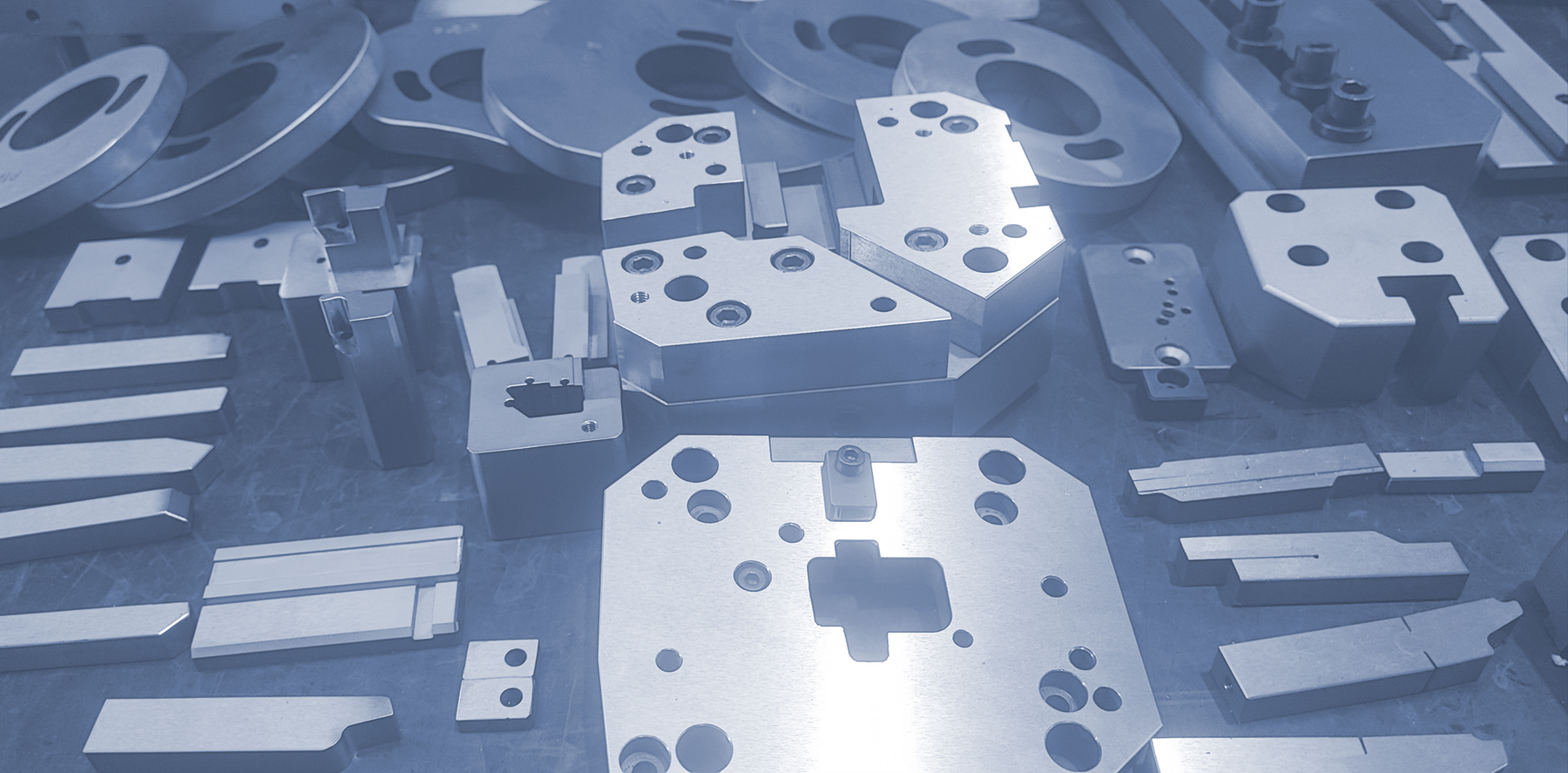

We always start from the choice of high-quality materials for the processing of components. The materials processed are steel, stainless steel, copper, brass, aluminum, both annealed and raw. Digital technology, however, is no less important. That’s why we integrated an MES system to support production to track the life cycle of products.

-

Experience

Ours is a family history, which is based on tradition. For us, “experience” means this: being able to carry on everything we have done in the past, keeping up with the present and looking to the future. Tradition, manual skills and know-how are our key words, which allow us today to transfer the know-how acquired in the construction of molds and equipment for bending, blanking, drawing, progressive molds and equipment.

-

Machinery

Investments in innovative and cutting-edge machinery to meet the needs of the market and our customers have always been a priority: presses from 10 to 200 tons, fast presses, Bihler bending machines (more reliable and functional), as well as an internal mechanical department to support the production of various molds, equipment and spare parts.