Sectors

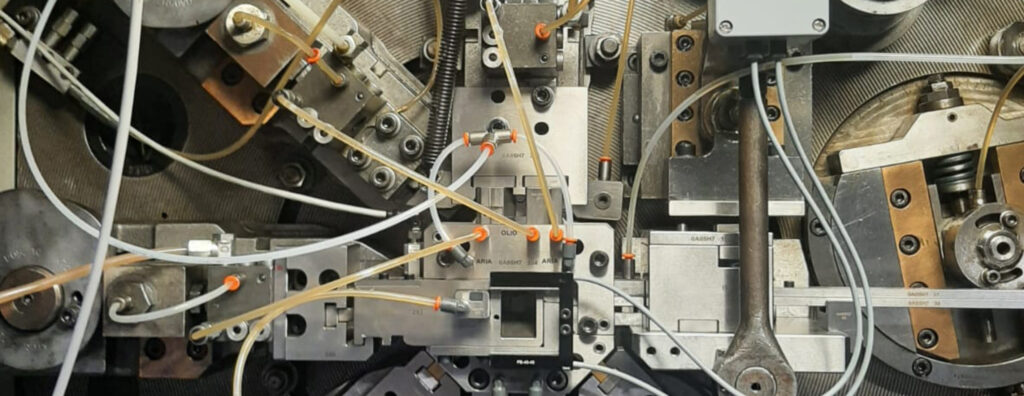

Design of equipment and molds

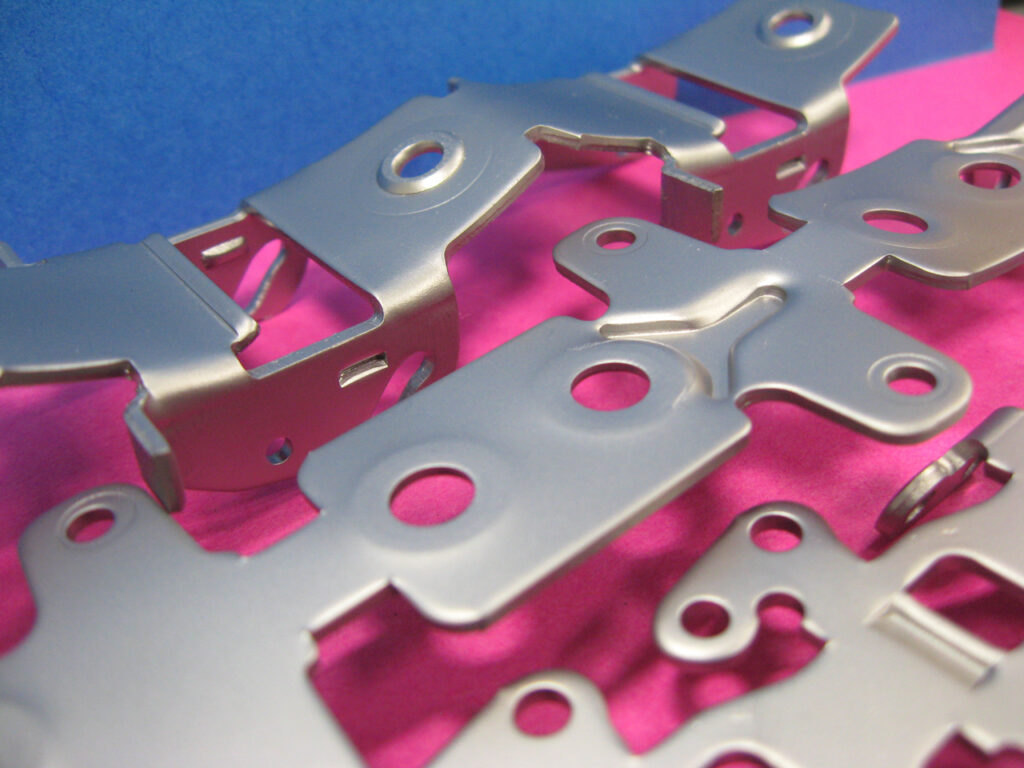

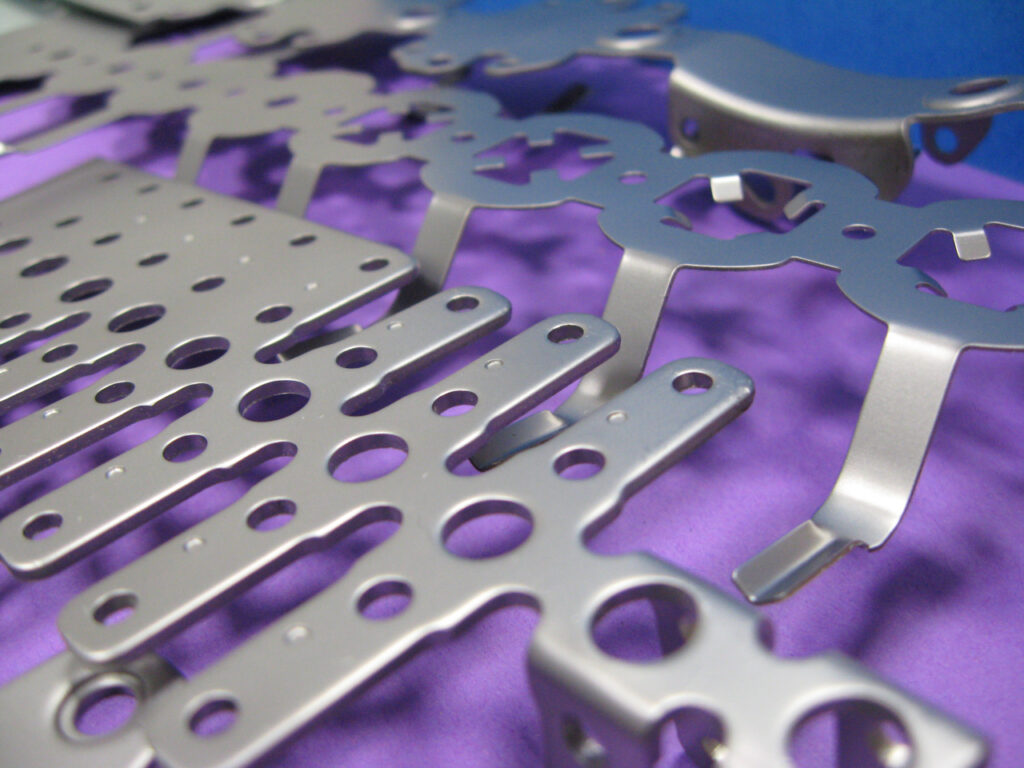

How We WorkWe design and manufacture any type of product dedicated to small metal components.

Our process:

PROJECT → PROTOTYPE → REALIZATION → TESTING → QUALITY CONTROL

For three generations, Melesi G has handed down all the competence, experience and professionalism acquired in the field, thanks to orders in the most varied sectors of components.

We work by supporting our customers starting from the development phase of new products, providing quality equipment, design systems with 3D modeling software and CAD CAM, up to the pre-series realization of the final product.

Thanks to a careful feasibility study, we can guarantee the quality of each equipment produced since its design. For us this is an essential starting point to customize and optimize the molds based on the expected production cycle. The result is a highly efficient service that lasts over time.

Construction of molds and equipment for bending, blanking, deep drawing and progressive molds in sintered steels, are just some of our areas of expertise.

Finally, we also provide assistance and maintenance services on existing molds.

Do you want to know the applications of our design method?